A Government Recognised Export House

Our infrastructure entails latest technology for the manufacturing process, including cold & hot forming, metal gathering, continuous heat treatment, precision machining and galvanizing. Further, the company is well equipped with all the modern testing equipment in our Mechanical Testing Lab. Expert technicians monitor the entire process starting from purchase of raw material till the finished products to ensure high quality International standards. We have full traceability in all operations and material lots. Every lot undergoes a strict checking at every stage of production. We provide test certificates of supplied material as per International accepted standards.

The company believes in continuous up gradation of technology and innovation which has kept it ahead of others in the field of Fasteners. The company's technological superiority combined with a highly skilled team with 40 plus years of experience in fasteners has made Hamidi an icon for quality and performance; gaining accolades worldwide from our reputed customers. Our manufacturing facilities keeping pace with technical advantages purely define our corporate dynamism ready to confront the future challenges, infusing innovative thinking with bold initiatives.

Hamidi is well equipped with latest technology cold forging machines capable of making bolts up to 1" diameter and 200mm in length. Cold forming enables us to manufacture better quality product with high accuracy in size control. With current cold forming infrastructure, we are capable to manufacture 500 metric tons of fasteners in a month

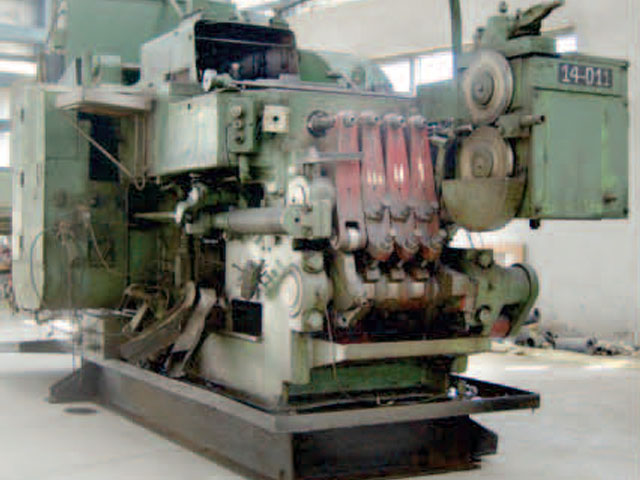

Hot forming helps us to make large diameter (Up to 64mm) and longer length bolts (up to 1500mm). With friction screw presses, hydraulic presses, induction heaters etc., we are capable of manufacturing 300 metric tons of hot forged fasteners per month.

According to a study of fasteners, majority of fastener rejections are due to faulty heat treatment. We have Mesh Type continuous heat treatment, which help us to provide better heat treated fasteners with minimal variations in lots.

We have a well-equipped material testing lab for testing fasteners as per international standards (ISO 898-1, ISO 898-2 etc.). Our Lab includes spectrometer Universal Testing Machine, Impact Test Machine, Cooling Chamber for Impact Test, Torque Testing Tools, Hardness Tester, Microstructure & Decarburization Testing Apparatus and Salt

We have in house hot dip galvanizing facility with capacity of galvanizing 10 metric tons of fasteners per day. Workers are properly trained according to our galvanization control plan suited to fulfill needs of international standards such as ISO 1461 and ISO 10684.

Well-designed bins, racks and trolleys enable quick and efficient material movement, helping us to achieve our goal of shorter delivery lead times.

Feel free to call or email Hamidi for any additional information you need or questions you may have. We`d be delighted to hear from you!

Get in Touch